Welding Power Supply

CE Certification

UF40 Features:

1. Up to 4KHz inverter frequency and precise feedback control make welding energy control more precise and rapid.

2. Dual pulse welding and each pulse can adjust the time, energy and energy control method.

3. Multiple welding energy control methods: constant current/constant voltage/constant power.

4. Full parameter monitoring of the welding process, with welding result data displayed in text and graphics.

5. Automatic evaluation of welding quality and signal output for easy backend processing in production

6. Multiple welding modes, such as universal welding, seam welding, remote control welding, etc

7. The serial communication function can transmit the result datas of each time to the computer

8. Multiple automated handshake signals for easy integration into automatic welding systems

9. The welding counter can accumulate all solder joints or only accumulate qualified solder joints

10. Can be matched with various welding heads and welding triggering methods

Application videos:

https://youtu.be/_eNqnMFGOzI

https://youtu.be/x0AYF6wMoro

https://youtu.be/Je038DG8FMI

https://www.youtube.com/shorts/tNStNu6wOCY

https://www.youtube.com/shorts/_eNqnMFGOzI

https://www.youtube.com/shorts/x0AYF6wMoro

https://www.youtube.com/shorts/eA31lRpQl3Y

https://www.youtube.com/watch?v=AV6ciVUvGF0&t=109s

https://www.youtube.com/watch?v=xq0UxBEi8pc

UF40 Welding Power Supply:

1. Net weight: 9KG

2. Dimension(mm): 195(W) * 318(H) * 320(D)

3. Cooling method: air cooling

4. Inverter frequency: 4Khz

5. Maximum welding current: 4500A

6. Power Supply: 3-phase,360VAC~410VAC/35A

7. Standby power consumption: 30W

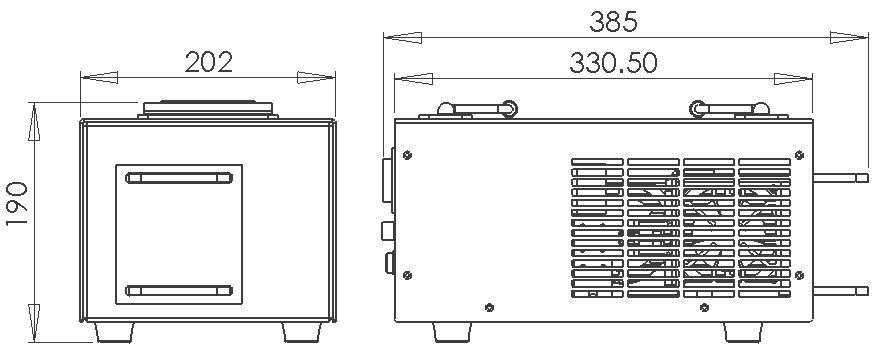

TR4000A Welding Transformer:

1. Net weight: 15KG

2. Dimension(mm): 202(W) * 190(H) * 385(D)

3. Cooling method: Air cooling

4. Maximum frequency: 10Khz

5. Maximum output current: 5KA

6. Duty cycle: 12%

1. Net weight: 14.5KG

2. Dimension(mm): 194(W) * 160.5(H) * 288.5(D)

3. Cooling method: Water cooling

4. Maximum frequency: 10Khz

5. Maximum output current: 5KA

6. Duty cycle: 36%

Welding samples: