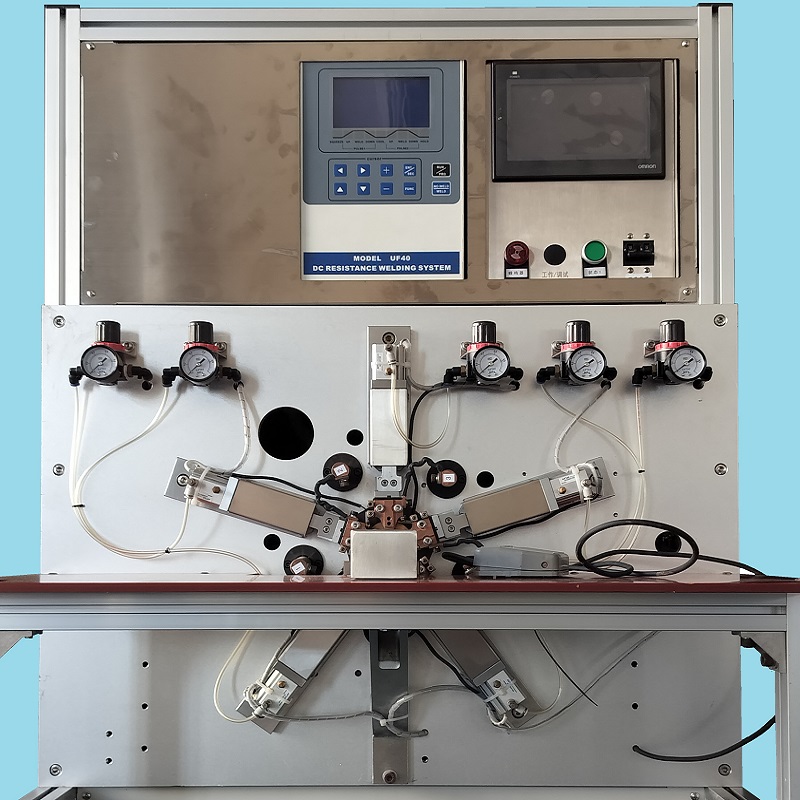

Rotor Welding Equipment

MCT5 3/5 series rotor commutator welding machine

Features:

1. Specially designed for 3-hook and 5-hook commutators.

2. Equipped with UF40 high-frequency inverter DC welding power supply to achieve high-speed and high-precision welding.

3. Each hook can independently set paremeters of welding and monitoring.

5. Due to the simultaneous descending of the welding head, the straightness of the rotor shaft and the true roundness of the commutator are ensured.

6. Equipped with specialized high-speed gas spring welding heads.

7. Up to 2400 rotors can be welded per hour.

1. Specially designed for 3-hook and 5-hook commutators.

2. Equipped with UF40 high-frequency inverter DC welding power supply to achieve high-speed and high-precision welding.

3. Each hook can independently set paremeters of welding and monitoring.

5. Due to the simultaneous descending of the welding head, the straightness of the rotor shaft and the true roundness of the commutator are ensured.

6. Equipped with specialized high-speed gas spring welding heads.

7. Up to 2400 rotors can be welded per hour.

Product Details

Videos:

https://www.youtube.com/watch?v=4dU2LEsR-1g

Specifications:

1. Power supply: 3-phase, 380VAC/40A2. One UF40 high-frequency inverter DC welding power supply

3. 5 TR4000A high-frequency inverter welding transformers

4. One TC01 switch

5. Five precision pressure welding heads with gas springs

6. Cooling method: air cooling

7. Working pressure range (Bar): 2.0~6.0