Welding Power Supply

ADP9 Dual Pulse Capative Energy Storage Welding Power Supply

Application:

The ADP9/DP875 energy storage precision spot welding power supply has the welding characteristics of short time, medium power, and high precision, which is particularly suitable for welding high-quality requirements such as honeycomb positioning of aircraft engines, honeycomb positioning of gas turbines, metal packaging of semiconductor and fiber optic components, sensor pin leads, high-power power battery packs, etc.

ADP9/DP875 can be equipped with various specialized welding heads, such as WBT-Q180AS for engine honeycomb positioning welding, WBT-SPQ500 and WBT-SPQ2T for metal packaging welding, WBT-Q180 for sensor pin lead welding, WBT-Q188Q for power battery pack welding, and more.

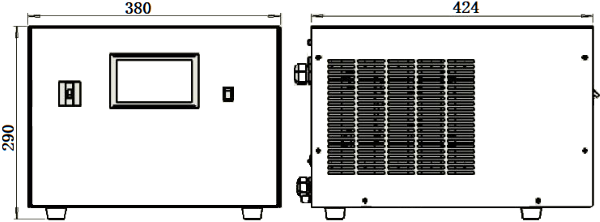

Welding power supply box:

![]()

1. Power supply: 1-phase, 205VAC ~ 235VAC/10A, 50Hz/60Hz

2. Dimension(mm): 380(W) * 290(H) * 424(D)

3. Net weight: 31KG

4. Maximum welding energy: 900 Joule

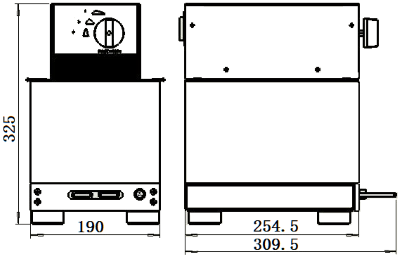

Welding Transformer specification:

1. dimension(mm): 190(W) * 325(H) * 309.5(D)

2. Net weight: 59.5KG

Features:

1. Compatible with multiple welding heads

2. Dual pulse welding function

3. Multiple welding working modes

4. Remote control mode, easy to embed in automatic welding equipment

5. 3 welding pulse width options: short pulse, medium pulse, long pulse

6. Equipped with welding current monitoring and waveform display functions

7. Has weak welding prevention function, effectively reducing the rate of welding defects

8. Multi functional welding counter, capable of accumulating all welding points or qualified welding points

9. High precision welding energy control can improve the quality and consistency of solder joints

10. Serial communication function, which can transmit the welding result data of each solder joint to the computer